How Vacuum Regulators Work

A vacuum regulator controls and stabilizes pressure through the use of inlet and outlet ports that allow higher pressure air into or out of the system as needed. Vacuum breakers and regulators operate under similar principles, but where a regulator will not allow air into the process line, a vacuum breaker will. Depending on the application, this may mean more energy expenditure to clear the air lines and adjust the system pressure.

Types of Vacuum Regulators

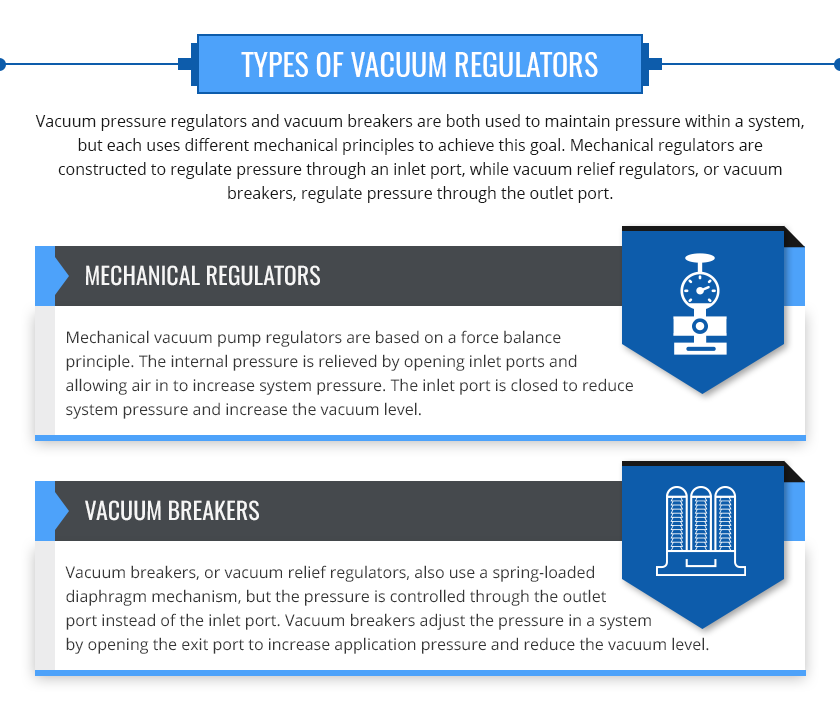

Vacuum pressure regulators and vacuum breakers are both used to maintain pressure within a system, but each uses different mechanical principles to achieve this goal. Mechanical regulators are constructed to regulate pressure through an inlet port, while vacuum relief regulators, or vacuum breakers, regulate pressure through the outlet port.

Mechanical Regulators

Mechanical Regulators

Mechanical vacuum pump regulators are based on a force balance principle. The internal pressure is relieved by opening inlet ports and allowing air in to increase system pressure. The inlet port is closed to reduce system pressure and increase the vacuum level.

A spring-loaded diaphragm is placed between the process vacuum and inlet port, allowing the diaphragm to expand and contract against the spring. The spring is tightened to ensure that the diaphragm’s movement automatically releases or restricts gas flow as needed to maintain appropriate pressure within the system.

Vacuum Breakers

Vacuum breakers, or vacuum relief regulators, also use a spring-loaded diaphragm mechanism, but the pressure is controlled through the outlet port instead of the inlet port. Vacuum breakers adjust the pressure in a system by opening the exit port to increase application pressure and reduce the vacuum level.

The spring-loaded diaphragm works in a similar fashion to mechanical regulators. As pressure in the system decreases and the vacuum increases, the diaphragm mechanism applies pressure to the vacuum regulator valve via a plunger, opening the valve and allowing more air into the system. As the system pressure increases, the diaphragm deflates, releasing the pressure on the plunger and closing the valve to allow the system pressure to decrease again.

What Does a Vacuum Regulator Do?

Vacuum regulators control the pressure within a system in a more efficient fashion than more traditional single-valve seats. The spring-loaded diaphragm mechanism throttles the air flow from either a pump or external ambient air source in order to better regulate internal pressure. Adjustable vacuum regulators allow operators to ensure that the system is operating at optimal pressure at all times, without the need for regular manual intervention.

Common Vacuum Regulator Applications

Vacuum regulators are highly useful in a variety of applications and industries. Common uses for vacuum regulators include:

- Airflow control

- Pressure stabilization

- Pump control

- Industrial liquid flow optimization

- Altitude simulations

- Food product packaging

- Reservoir regulation

- Fuel cell efficiency

- Flow meters

- Medical and dental equipment

- Dairy milking machinery

- HVAC equipment

- Laboratory and analytical instruments

The correct vacuum regulator will help regulate the flow of gases and liquids for applications without the need for manual flow control. This greatly reduces energy and labor costs and increases the overall efficiency of the system.

Vacuum Regulators from Airtrol Components

Since 1977, Airtrol Components, Inc. has been a leading provider of high quality precision pneumatic components. As a family-owned and -operated business, we are dedicated to providing miniature pneumatic parts for a broad range of light-to-medium duty applications that require exceptional precision. Our lightweight components are designed and integrated by highly experienced and knowledgeable engineers and specialists, so our customers always know that they are getting the best available part for their application.

For more information on our superior quality vacuum regulators and other pneumatic components, contact us today.